Description

MWTX64-0.3/0.6-130 tube has a double focus designed for use with standard-speed anode rotation for high energy radiographic and cine-fluoroscopic operations. The integrated high quality tube with glass design has two super imposed focal spots and a rein-forced 64 mm anode. The high anode heat storage capacity ensures a wide range of applications for standard diagnostic procedures with conventional radiographic and fluoroscopy systems. A special designed anode enables an elevated heat dissipation rate which leads to a higher patient through- put and a longer product life. A constant high dose yield during the entire tube life is ensured by the high density rhenium-tungsten compound target. Ease of integration into system products is facilitated by extensive technical support.Specifications

| Maximum Operating Voltage | 130KV |

| Focal Spot Size | 0.3/0.6 |

| Diameter | 64mm |

| Target Materia | RTM |

| Anode Angle | 10° |

| Rotation Speed | 2800RPM |

| Heat Storage | 200kHU |

| Maximum Continuous Dissipation | 475W |

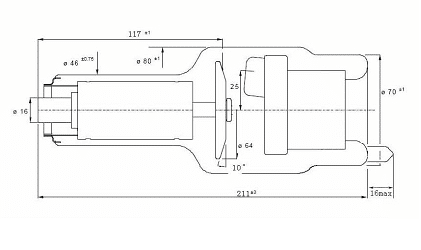

Outline Drawing

Applications

MWTX64-0.3/0.6-130 rotating anode X-Ray Tube is especially designed for Medical diagnosis x-ray unit. Rotating anode X-ray tube for the purpose of fluoroscopy X-ray procedures.Filament Characteristics

| Small filament | fmax=5.4A ,Uf=7.5±1V |

| Big filament | Ifmax=5.4A,Uf=10.0±1V |

| Inherent Filtration | 1mmAL |

| Maximum Power | 5KW/17KW |

Competitive Advantage

Standard speed anode rotation with silenced bearings High density compound anode (RTM) Elevated anode heat storage capacity and cooling Constant high dose yield Excellent lifetimeCautions!

X-ray tube will emit X–ray when it is energized with high voltage, Special knowledge should be required and cautions need to be taken when handling it.

1. Only a qualified specialist with X-Ray tube knowledge should assemble, maintain and remove the tube. When mounting tube inserts adopt proper caution, in order to avoid glass bulb breaking and fragments projection. Please use protective gloves and glasses.

2. Tube insert connected to H.V. supply is a radiation source: be sure to take all necessary safety cautions. 3. Wash thoroughly with alcohol the external surface of tube insert (care of fire risk). Avoid contact of dirty surfaces with cleaned tube insert.

4. Clamp system inside housing or self-contained units must not mechanically stress the tube.

5. After installation, check the right working of the tube (no fluctuation of tube current nor crackling).

6. Comply with insert thermal parameters, planning and programming the exposure parameters and cooling pauses. Housing or self-contained units must be provided with an adequate thermic protection.

7. Voltages indicated in charts are valid for transformer supplied with ground center.

8. It is extremely important to observe the connection diagram and the grid resistor value. Any change could modify the dimensions of the focal spot, also varying diagnostic performances or overloading anode target.

9. Tube inserts contain environment polluting materials, particularly lead liner tubes. Please apply to qualified operator for waste disposal, according to local regulation requirements.

10. When any abnormalities are found during operation, immediately switch off the power supply and contact the service engineer.

Filament emission characteristics

loading chart